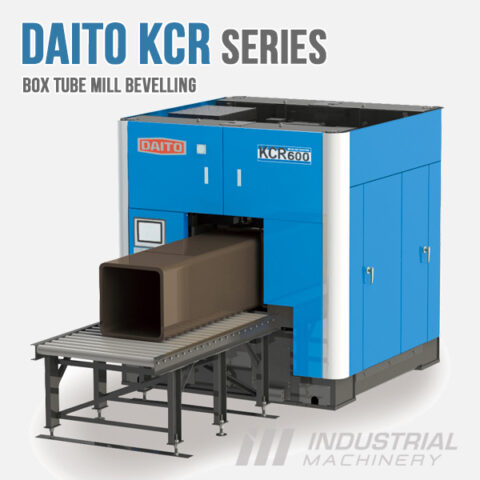

Australia’s favourite Beam Line.

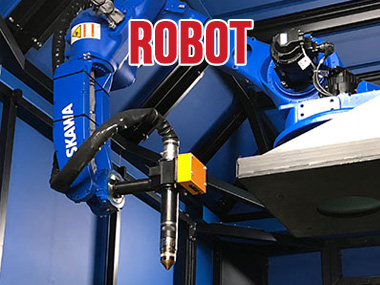

Introducing the Daito DCM: Revolutionizing Steel Fabrication

Experience the future of steel fabrication with the Daito DCM Combined Drilling Plasma Coping Robot machine. This state-of-the-art system is designed to transform your steel workshop and elevate your fabrication capabilities. Here’s what makes it a game-changer:

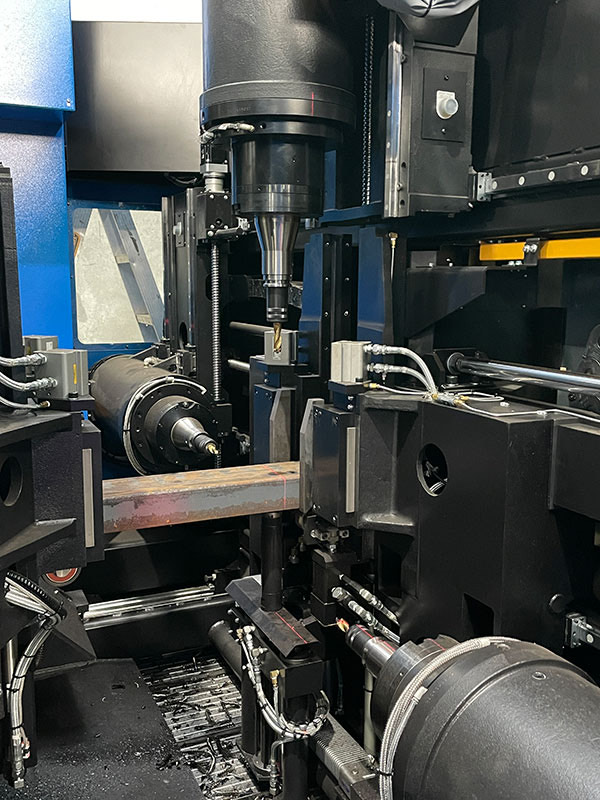

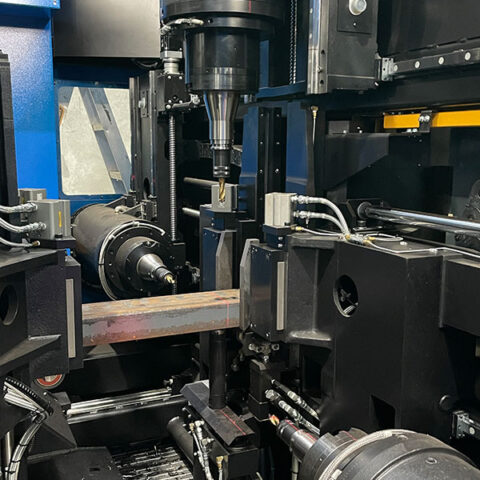

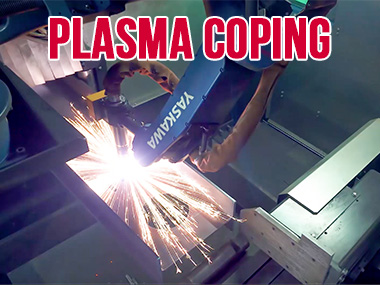

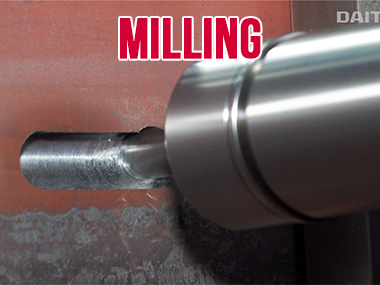

- Versatile Functionality: The Daito DCM combines drilling, plasma cutting, and coping in a single, integrated machine. This versatility streamlines your processes, saving time and effort.

- Precision and Speed: Benefit from the precision of computer-controlled operations and the speed of robotic automation. Achieve consistent, high-quality results on every project.

- Space Optimization: Maximize your workshop space with a compact design that combines multiple functions, reducing the need for multiple machines and workstations.

- Enhanced Productivity: Say goodbye to material handling hassles. The Daito DCM’s seamless workflow ensures efficient material processing, eliminating the need for transferring materials between machines.

- Labor Efficiency: This machine demands minimal operator involvement, reducing labor costs and optimizing manpower.

- Cost Savings: Invest in one machine that replaces multiple standalone devices. Save on equipment costs, maintenance, and floor space.

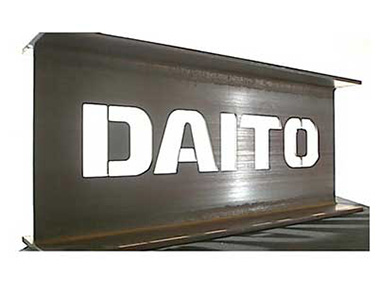

Unleash the power of the Daito DCM Combined Drilling Plasma Coping Robot machine and take your steel fabrication to new heights. Embrace the future of efficiency, precision, and cost-effectiveness in your workshop.

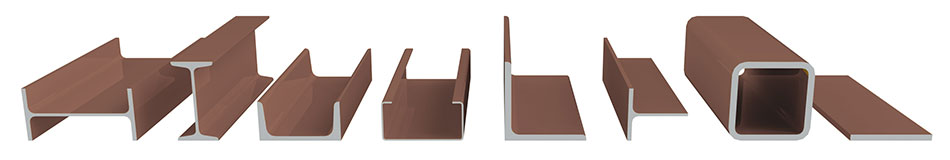

Process these profiles all-in-one machine

DCM features

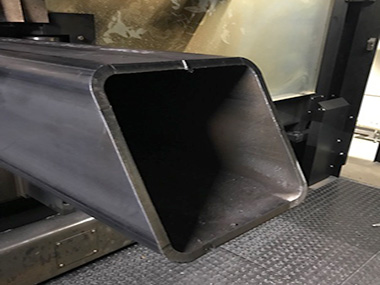

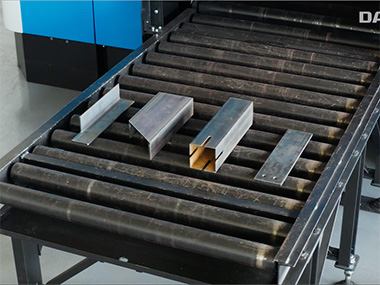

Processing samples

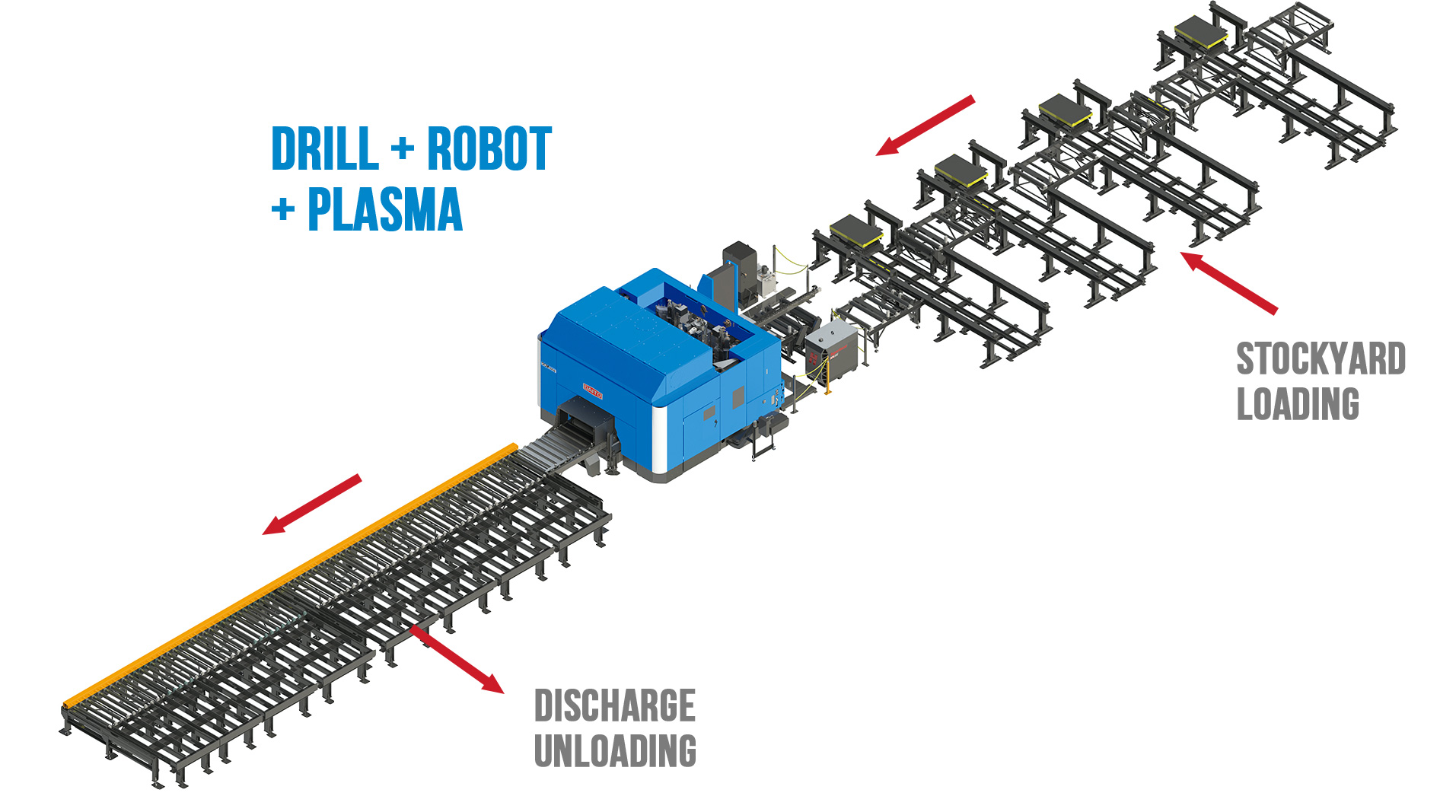

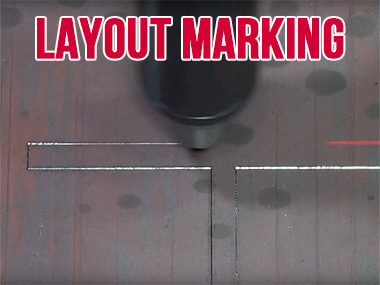

Layout