Maruhide Pipe Coaster MA Series

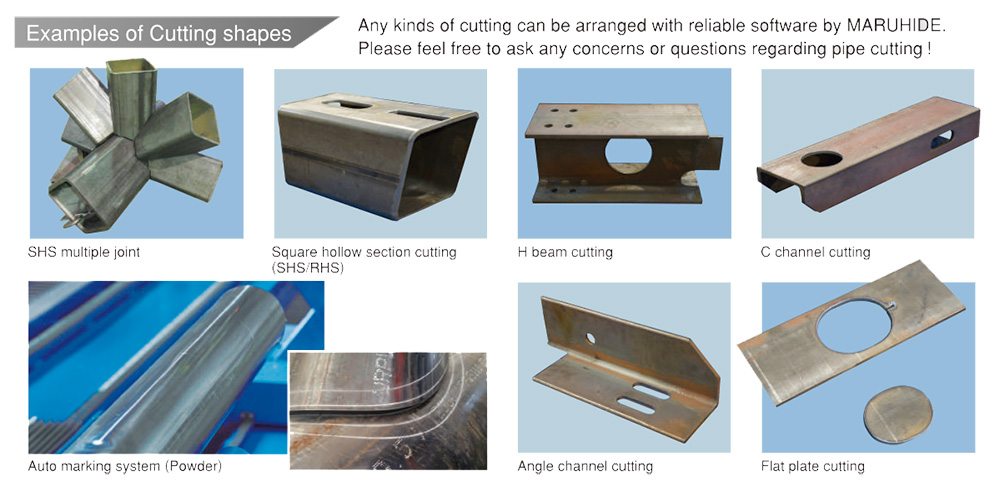

Cutting shapes

Discover the new MARUHIDE PIPE COASTER MA Series, now 2 times faster, and experience a revolutionary leap in CNC automatic pipe cutting.

Experience the best in pipe cutting technology with the MARUHIDE PIPE COASTER MA Series.

| Specifications / Model | 400MA | 650MA | 1000MA | 1350MA | 1500MA |

|---|---|---|---|---|---|

| Cutting pipe diameter(mm) | 34 to 406.4 | 60.5 to 660.4 | 76.3 to 1016 | 165.2 to 1371.6 | 267.4 to 1524 |

| Axis numbers (model) | 5 axis (MA5)/ 6 axis (MA6)/ 7 axis (MA7) | ||||

| Interactive cutting software (PIPE STUDIO) | Standard | ||||

| Interactive operation panel / Remote control panel | Standard | ||||

| Windows network | Standard | ||||

| Torch travel length (mm) | 1000 / 3000 / 6000 / 9000 / 12000 / 15000 / 18000 | ||||

| Pipe trolley numbers | Torch rail 1000 to 3000 mm x2sets / 6000 to 9000 mm x 3sets / 12000 mm or more x5sets | ||||

| Self-centering pipe chuck | 400MA, 650MA, 1000MA 4 or 5 jaws / 1350MA, 1500MA 3jaws | ||||

| Laser sensing system | Standard | ||||

| Plasma cutting machine | Standard | ||||

| Oxy/fuel cutting | Option | ||||

| Manual pre-heating unit | Option | ||||

| Auto pre-heating unit | Option | ||||

| Auto pre-heating system | Option | ||||

| Motorized clamping system (chuck) | Option | ||||

| Motorized traveling system (pipe trolley) | Option | ||||

| Touch sensor (side) | Option | ||||

| Auto marking system (powder) | Option | ||||

| Auto marking system (inkjet) | Option | ||||

| Cutting system for rear side of chuck | Option | ||||

| Loading-unloading system with chuck up/down function | Option | ||||

| Square rotator | Option | ||||

| Fume collector | Option | ||||

| Interactive cutting software (PIPE STUDIO) | Standard |

| PIPE STUDIO for PC | Standard |

| Nesting software | Standard |

| Data conversion software for AUTOCAD | Standard |

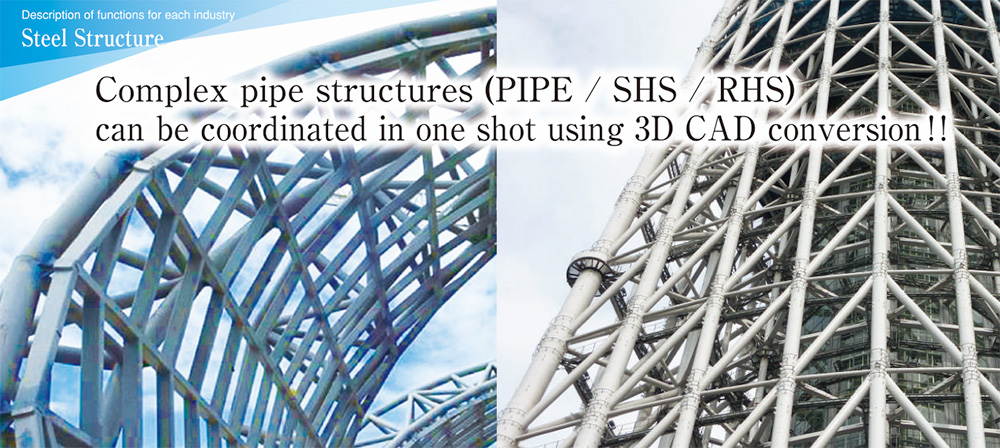

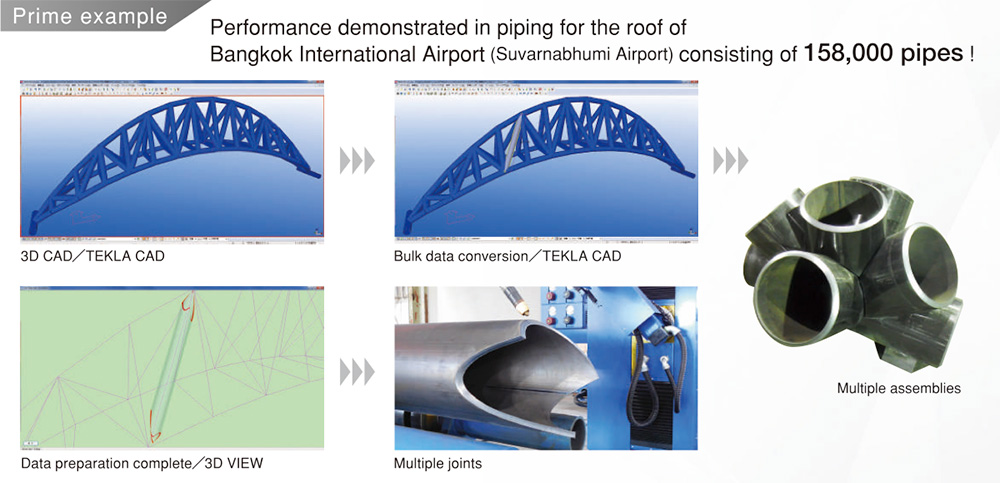

| Data conversion doftware for TEKLA | Option |

| Data conversion doftware for CSV | Option |

| SHS, RHS cutting software | Option |

| Structural shaped steel and flat bar cutting software | Option |

| DXF template export software | Option |

| Marking software | Option |

| Foot print for welding software | Option |

| Cutting software for taper tube | Option |

| Cutting software for AWS/API | Standard |