Features

- High RPM, high torque spindle

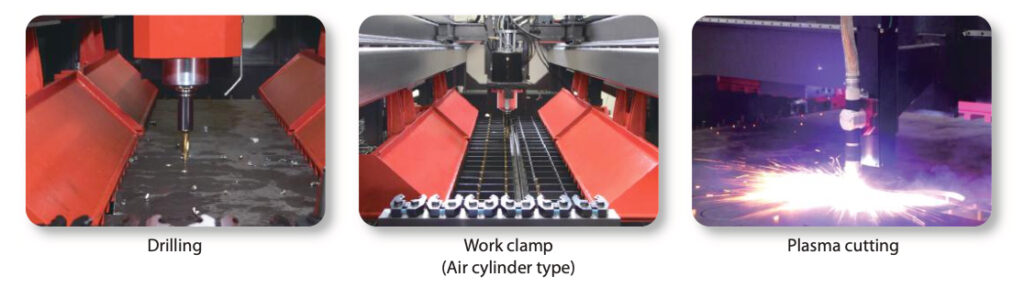

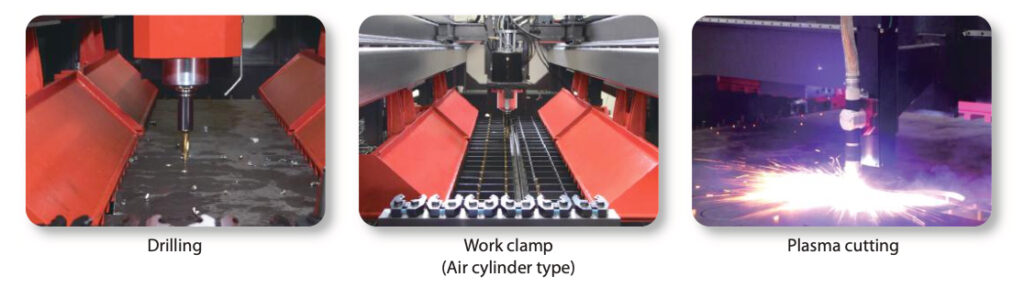

- Fast drilling with tungsten carbide drill

- Fast cutting, no preheating necessary

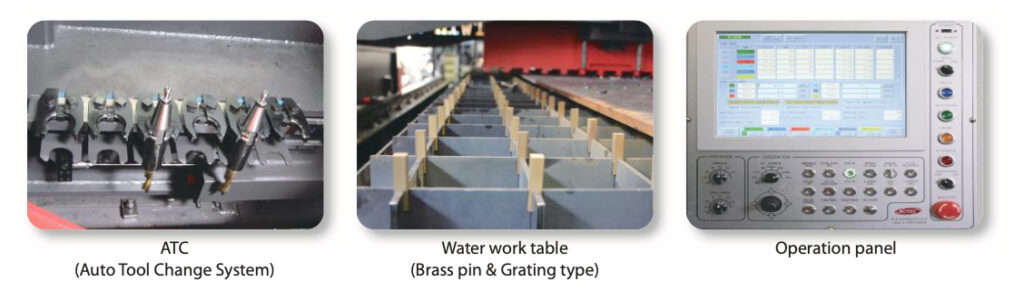

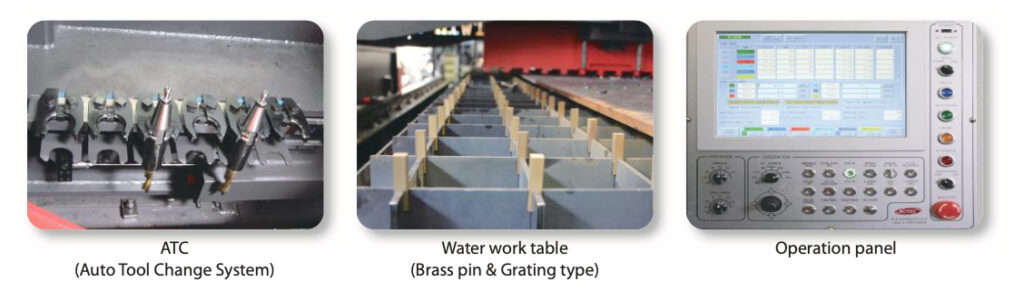

- ATC (Auto Tool Change)

- Multi-production in small space

- Auto nesting program

https://youtu.be/SeV8wYAMILg?si=LE4gENd1m4nYXAC4

Kotec multi-function plate drilling and plasma cutting machine.

Capacity: 6m | 9m | 12m | 20m | 30m+

Features

https://youtu.be/SeV8wYAMILg?si=LE4gENd1m4nYXAC4

| Travelling | Dual Gantry type |

| Effective cutting width | 2500 / 3000 mm |

| Effective cutting length | 6000 / 9000 / 12000 mm |

| Drilling Capacity | Ø14 ~ Ø50mm |

| Max. Plate Thickness | 50mm |

| Type of Drill | Oil Hole, Tungsten Carbide Drill, Straight shank |

| Spindle Drill Holder | BT-50 |

| Spindle Motor | Built-in Spindle 18Kw, 8P |

| Spindle RPM | 1800 RPM (Inverter controlled) |

| ATC (automatic tool changer) | 6 tools changer included |

| Oil mist Coolant system | |

| Drill Feeding | LM / Ball screw type, Servo Motor |

| Travelling | Gantry Move by Servo motor |

| Travelling Speed | Max 30m/min. |

| Vertical clamping while drilling | Air cylinder type 4 sets |

| Worktable type | Dry bed |

| Plasma | Hypertherm XPR-300 |

| Fume collector Optional | |

| Air compressor excluded | |

| Controller | Sentrol CNC controller, or equivalent. |