Australia’s favourite Beam Line.

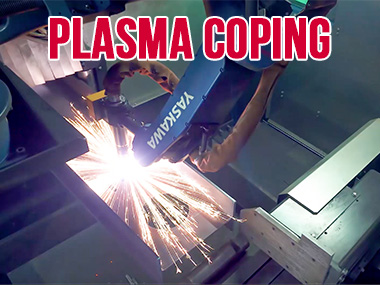

The Daito CR1000 Plasma Coping Robot enables steel fabricators to become more efficient through several key mechanisms:

- Automated Coping: The robot automates the coping process, reducing the need for manual labor and minimizing the risk of errors.

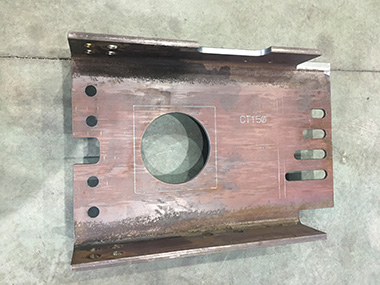

- Precision Cutting: The robot offers precise plasma cutting, ensuring accurate coping of steel profiles, which reduces material wastage and the need for rework.

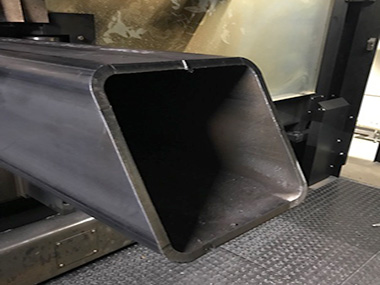

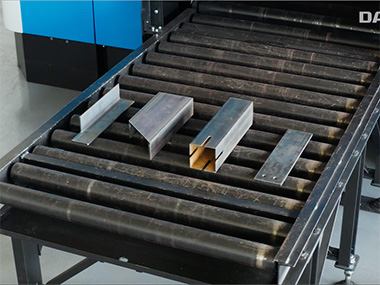

- Versatility: It can cope various steel profiles, such as beams, channels, and angles, providing versatility and adaptability to different fabrication needs.

- Optimized Material Usage: The robot’s automated optimization feature minimizes material wastage by utilizing materials efficiently, resulting in cost savings.

- Increased Productivity: By automating repetitive tasks, fabricators can complete projects more quickly, leading to higher overall productivity.

- Reduced Setup Time: The user-friendly interface and programming capabilities of the robot reduce setup time, allowing fabricators to start coping tasks more swiftly.

- Consistent Quality: The robot ensures consistent coping quality, reducing the likelihood of errors and rework.

In summary, the Daito CR1000 Plasma Coping Robot streamlines the coping process, enhances precision, and boosts productivity, making steel fabricators more efficient and competitive in their industry.