A Strong Partnership for Australia & New Zealand

The partnership between Daito-Seiki Japan and Industrial Machinery Sales & Service (IMS) sets a new benchmark for structural steel processing in Australia and New Zealand.

A global leader, Daito-Seiki is renowned for precision, innovation, and reliability. Their CNC drilling machines, high-speed bandsaws, and robotic plasma coping systems deliver accuracy, speed, and durability. With a focus on multi-tasking machines, Daito-Seiki helps fabricators maximise space, cut labour costs, and boost productivity — keeping them competitive in a demanding market.

By combining Daito-Seiki’s world-class technology with IMS’s local expertise and service, customers gain more than machinery. They receive a complete productivity solution that streamlines operations, improves efficiency, and provides long-term value.

This partnership gives steel processors across Australia and New Zealand direct access to the most advanced machinery, dependable support, and future-ready solutions to drive growth and success.

About Daito-Seiki Japan

Daito Machinery

Precision machines for structural steel processing

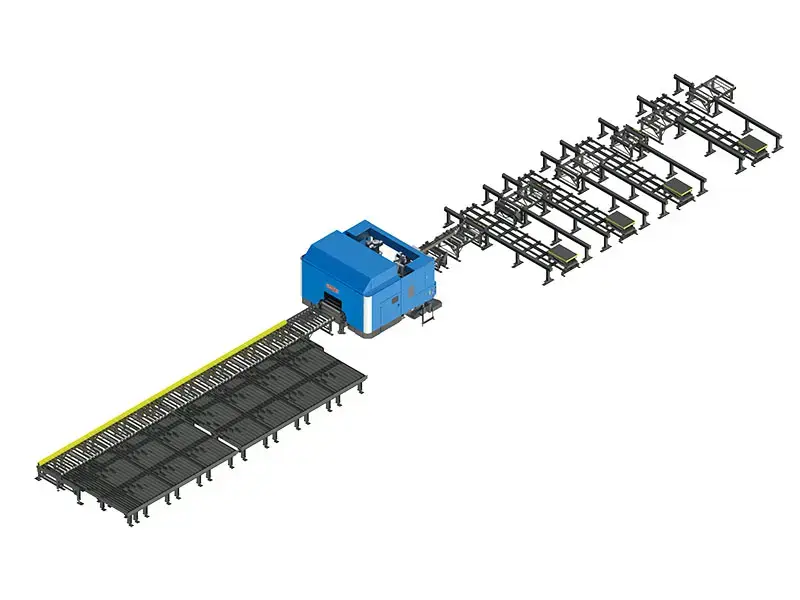

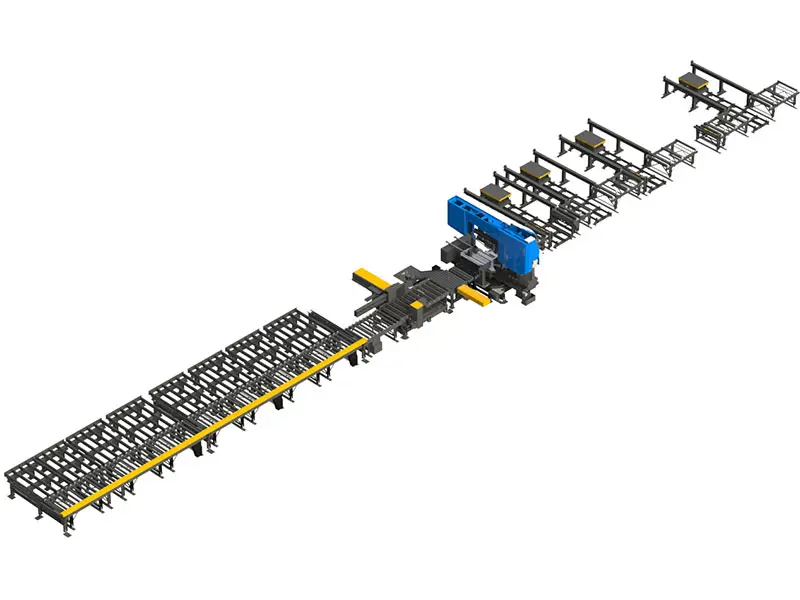

Fully Customisable Beam Lines

With Daito’s groundbreaking unitised machines and the innovative beam line configuration, achieving your desired outcomes for configuration and layout has never been easier.

Beam Lines Explained

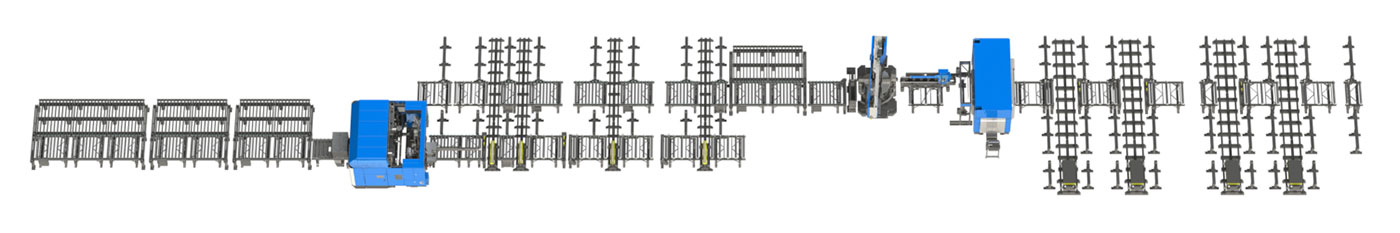

TANDEM LINE

- Drill & saw back-to-back

- Minimal idle time, maximum throughput

- Compact footprint

- Suits workshops with limited space & varied jobs

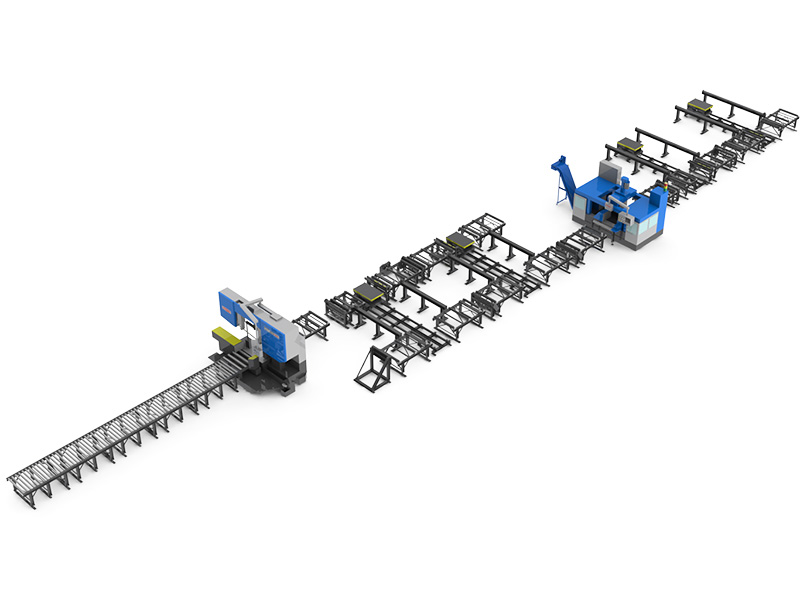

SPLIT LINE

- Drill & saw operate separately

- Higher production capacity

- Best for large workshops, long runs & less job variety

COMBINED LINE

- Multiple machines in one (Drill Robot Plasma or Drill Saw)

- Saves space & reduces costs

- Simplifies scheduling without sacrificing output

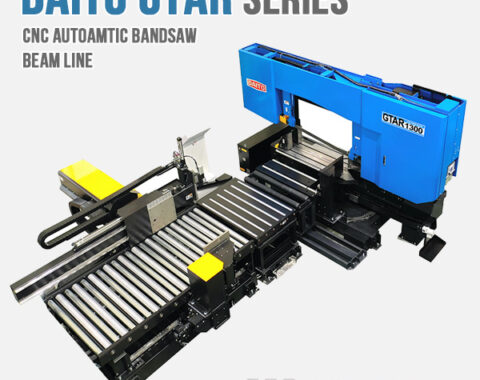

SAW ONLY LINE

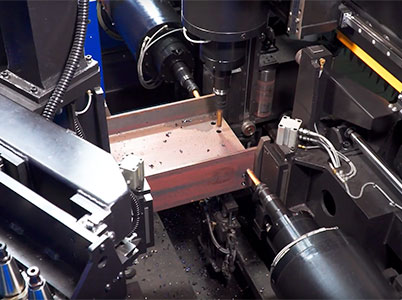

- Fast, accurate cutting only

- CNC auto feeding for efficiency

- Ideal for high-volume, everyday cutting

Advanced Features

Engineered for Real-World Workshops: Advanced features built to boost productivity, reduce errors, and maximise return on investment.

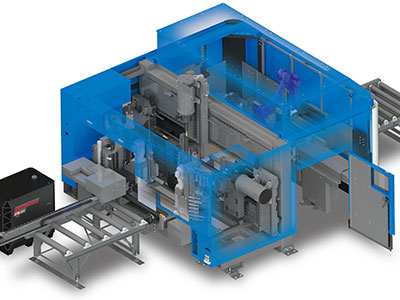

Combined Machines – Workshop Space Saver

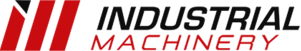

Multi-tasking CNC systems combine drilling, sawing, coping and more in one footprint, saving floor space, cost, and time while boosting output.

Layout Marking – Time Saver

Drilling units create fast, clean weld layout lines and letters on all four sides of the profile, reducing errors and manual work.

Advanced Material Handling – Labour Saver

Smart loading/unloading systems handle a wide range of profiles with less labour, faster throughput, and scalable investment options.

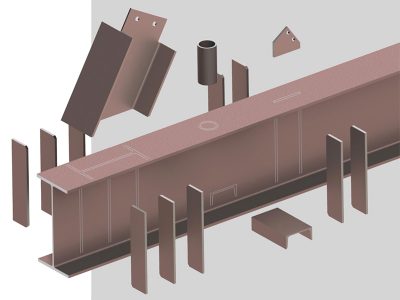

Robot Technology – The Future is Now

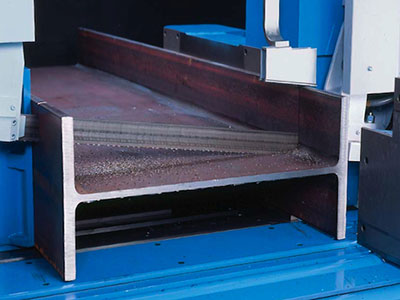

Daito leads with robotic plasma coping (CR Series) and combined drill/coping lines (DCM). Robotic welding systems are also on the horizon, setting the standard for the next generation of steel fabrication.

Meet The Family

From drilling and sawing to robotic coping – proven Japanese engineering with endless capability for fabricators worldwide.

Drilling and Sawing

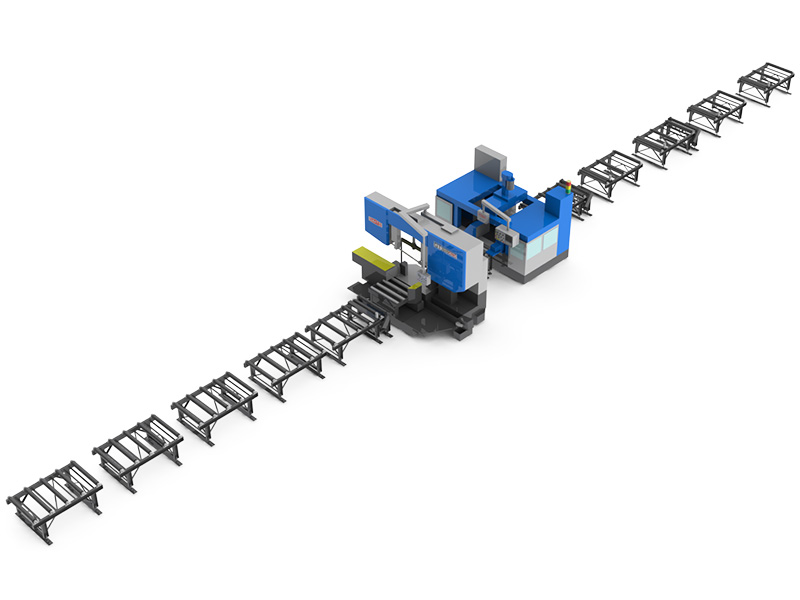

Daito CUD / GTR Drilling & Sawing Beam Line

- Unrivaled Performance

- Advanced Configuration with 3 Independent Drilling Spindles

- Handles Milling and Tapping

- Precision Layout Marking

- Double Mitre Capability

- Full Digital Control for Precision

- Smooth and Rapid Cutting with Linear Guides

- Dual Cooling

Daito DB 500 Drill Saw Beam Line

Plasma Coping Robot

Daito DCM Combined Drilling Coping Marking Beam Line

- All-in-One Efficiency

- High-Precision Drilling with

Daito CR Plasma Coping Robot Beam Line

- Max. Capacity: CR1000 (1000mm) - CR1300 (1300mm)

- Precise Plasma Cutting

- Versatile Coping

- Enhanced Efficiency

- User-Friendly Interface

- Optimal Material Usage

- Reliable Performance