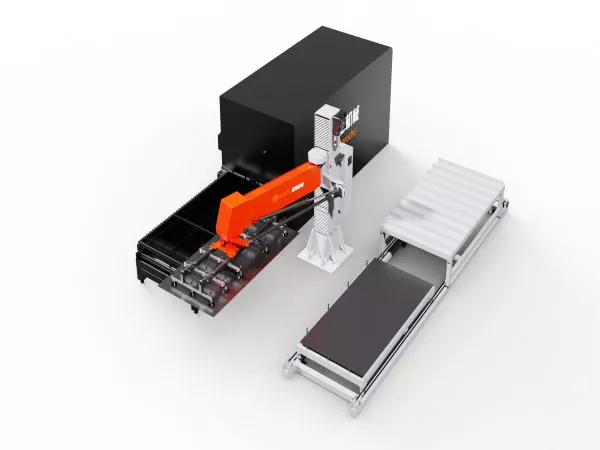

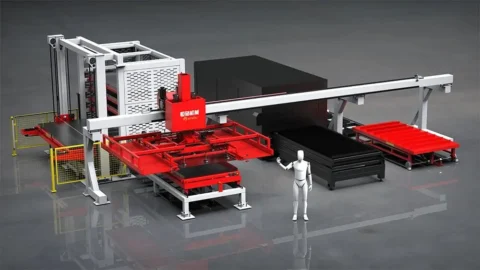

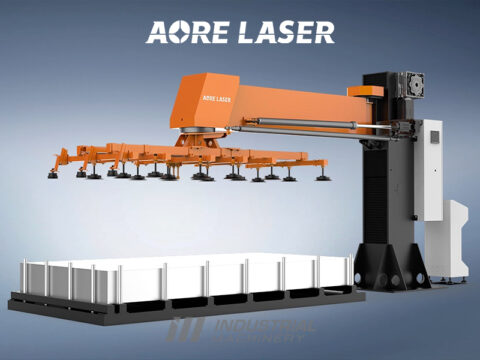

The IMS Servo Loading Arm is a next-generation automated sheet-handling system engineered for workshops that demand speed, accuracy and safe, repeatable loading of CNC laser cutting machines. Built with a servo-driven swing arm and a full PLC control system, it delivers precise positioning and smooth movement, even when handling heavy or large-format sheets.

Unlike conventional robotic arms—which often struggle in confined spaces or require complex programming—the IMS servo arm offers intuitive touchscreen controls, 360° rotation, independent pitch/yaw/roll motors, and fast setup for new jobs. The result is a flexible, highly efficient handling solution ideal for high-throughput laser cutting, automated production lines and modern industrial environments.

The arm offers exceptional accuracy, with ±0.1 mm positioning tolerance and 2000 mm operational reach. Its vacuum lifting system provides secure, damage-free sheet handling, and can be configured for various sheet sizes from 3015 mm up to 4020 mm formats. With options ranging from 200 kg up to 1000 kg payload capacity, it integrates seamlessly into any laser cutting workflow that requires both speed and safety.

Designed for demanding industrial applications, the IMS Servo Loading Arm enhances productivity, reduces labour requirements, and ensures consistent loading performance—even in compact workshop layouts.