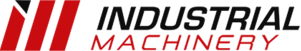

The IMS Pneumatic Loading Arm is an industrial-grade sheet handling system engineered for safe, fast and damage-free loading of CNC laser cutting machines, punch presses and bending machines. With lightweight structure, smooth movement and simple controls, it delivers high efficiency in busy workshops where frequent, short-distance lifting is required.

The IMS Pneumatic Loading Arm is an industrial-grade sheet handling system engineered for safe, fast and damage-free loading of CNC laser cutting machines, punch presses and bending machines. With lightweight structure, smooth movement and simple controls, it delivers high efficiency in busy workshops where frequent, short-distance lifting is required.

Using a powerful vacuum system with multiple suction cups, the IMS loading arm grips sheets securely without scratching or distortion. The unit can be operated manually or via remote control, allowing precise horizontal positioning for accurate and repeatable loading. Its column-mounted design provides excellent reach, while the low-friction wheel system ensures smooth, effortless travel—even at maximum load.

Built with high-quality steel, rubber and industrial-grade components, the IMS Pneumatic Loading Arm offers long-term durability with minimal maintenance. Safety is prioritised with air cut-off protection, anti-collision features and a vacuum pressure protection system to prevent accidental release. Fixed installation via anchor bolts makes it suitable for any fabrication shop requiring reliable sheet handling for daily operations.

Available in multiple load capacities and sizes, the IMS Loading Arm is compatible with steel, stainless steel, aluminium, glass, composite materials, acrylic, and more—making it a versatile solution for laser cutting operations, manufacturing plants, sheet-metal workshops, material distributors and industrial production lines.