The IMS Automated Sheet Metal Storage System is more than a storage rack — it is a complete re-engineering of how modern fabrication shops handle material flow. Built for manufacturers who want to remove bottlenecks, reduce forklift dependency, and keep their laser cutters running, this system automates the entire process of storing, retrieving, and delivering sheet metal.

In traditional workshops, operators spend significant time manually searching through stacked plates, moving material around with forklifts, risking sheet damage, and leaving high-value machinery idle. The IMS system eliminates that hidden cost by turning your raw material inventory into a smart, high-density automated vault. Using PLC control and a touchscreen interface, operators simply select the required sheet, and the system retrieves it automatically — safely, accurately, and without physical labour.

Centralised & Intelligent Control

All materials are stored within a single automated structure, replacing scattered floor stacks with an organised, digital inventory. Automatic warehousing, retrieval, and onboard weight detection ensure sheets are stored safely and efficiently. The integrated control system allows classification by thickness, grade, material type, or job number, giving you real-time visibility and complete confidence in your inventory.

Engineered for Precision & Longevity

A heavy-duty linear guide and chain-drive system ensures smooth and precise movement under full load. With 3-tonne and 5-tonne per-layer options, high-strength steel construction, and engineered low-deflection pallets rated at 667 kg/m², the IMS system is built to operate reliably for decades.

Customised for Your Workshop

Every factory is different, which is why the IMS system is fully customisable. Choose floor height, number of pallets, load rating, and sheet sizes — from 3015 mm up to 6020 mm and beyond. The system can be adapted for steel, aluminium, stainless, non-ferrous metals, or delicate materials requiring specialised support.

A Tangible, Measurable Advantage

The 3015 model occupies just 4.8 × 4.8 m (approx. 23 m²), consolidating up to eight different sheet sizes into one compact footprint. This reclaimed floor space can be used for an additional laser, bending cell, or improved workflow layout — without expanding your building.

One-person operation eliminates the need for continuous forklift work, reduces labour costs, and supports the transition toward lights-out or semi-autonomous manufacturing cells. Integration with laser cutters, punch presses, and automated loading systems transforms your workshop into a connected, uninterrupted production line.

Who It’s Designed For

The IMS Automated Sheet Metal Storage System is ideal for manufacturers who:

- Need to expand capacity without building extensions

- Handle multiple material types across small-batch or high-mix production

- Want to reduce forklift use and improve safety

- Are building automated processing cells or pursuing lights-out manufacturing

- Require perfect sheet condition for high-value work (aerospace, automotive, architectural steel, aluminium fabrication)

This system is an investment in long-term efficiency, safety, and growth — a foundation for the smart factory of the future.

Single Tower

Double Tower

Multi-Tower

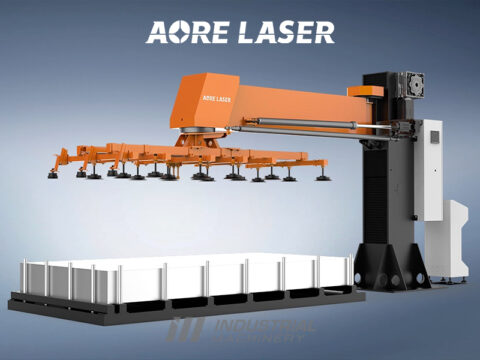

Connect to Laser Cutting Machine – Fully Automatic Loading / Unloading and Storage